- Welcome to Anhui Lanyi New Materials Co., Ltd

- Service Mobile:+86 19508030823

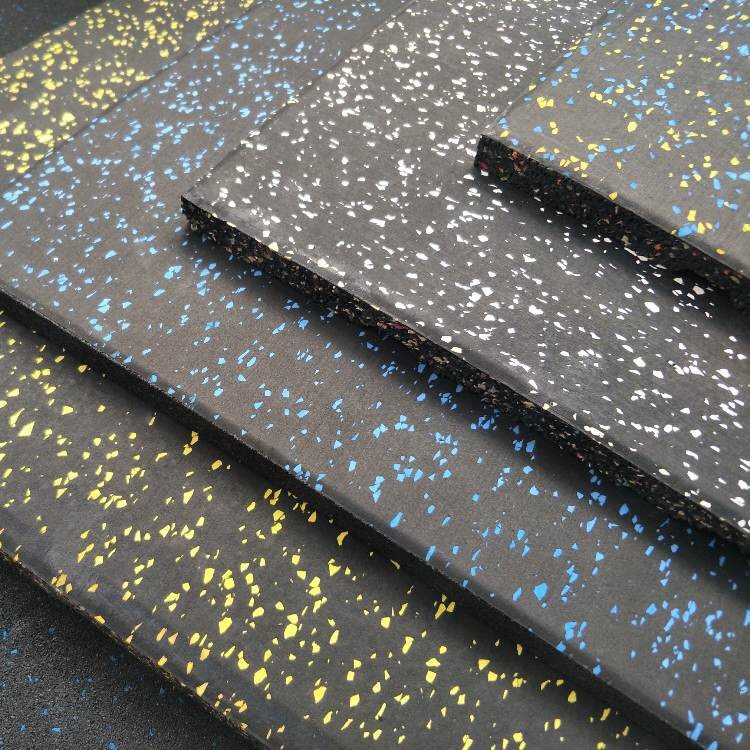

Rubber flooring is an elastic floor decoration material made mainly from natural rubber and synthetic rubber, combined with polymer materials. Its core components are polyvinyl chloride (PVC) or polypropylene (PP), and some products add glass fiber, cloth fiber reinforcement layer or nano antibacterial agent to enhance stability and functionality.

Environmental protection and safety

The raw materials do not contain harmful substances such as formaldehyde and heavy metals, and have passed SGS environmental certification. Some products meet food grade standards and are suitable for hygiene sensitive scenarios such as kindergartens and hospitals.

There is no discharge of wastewater or exhaust gas during the production process, and waste materials can be recycled and reused.

Excellent anti slip and shock absorption performance

Surface matte treatment, wet friction coefficient ≥ 0.5, more astringent when in contact with water, effectively preventing slipping.

The elastic buffer layer can absorb 70% of the impact force, reducing the risk of sports injuries, and is suitable for high-intensity use scenarios such as gyms and dance studios.

Durability and environmental adaptability

Strong weather resistance, able to withstand temperature differences of -40 ℃ to 100 ℃, with an outdoor service life of over 5 years.

Corrosion resistant, acid and alkali resistant, suitable for special environments such as laboratories and factories.

Sound absorption and comfort

Structural design can reduce 20 decibels of noise, reduce floor sound transmission, and improve indoor acoustic environment.

Soft materials provide a “smooth but not astringent” foot feel, relieving joint fatigue.

相关推荐

- Sports series PVC plastic flooring: an innovative solution for professional sports spaces

- Suspended flooring: innovative application of modular multifunctional flooring materials

- LENEN New Materials Co., Ltd.

- Gym rubber floor

- Homogeneous transparent plastic flooring, hospital specific antibacterial and environmentally friendly