- Welcome to Anhui Lanyi New Materials Co., Ltd

- Service Mobile:+86 19508030823

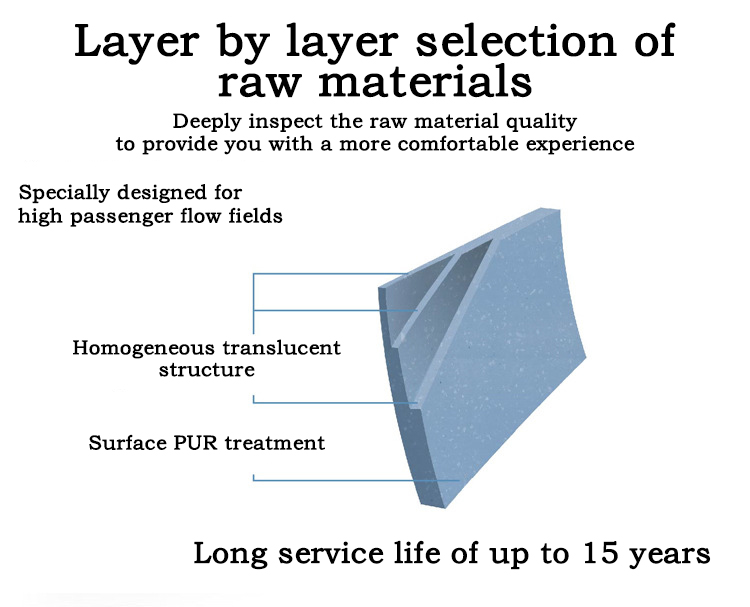

Homogeneous transparent PVC plastic flooring is an elastic flooring material made of materials such as polyvinyl chloride (PVC) and fillers (such as stone powder). Its core feature is consistent material throughout, that is, it is composed of the same components from the surface to the bottom layer. This structure allows it to maintain its original pattern and performance even after wear, especially suitable for high flow areas. And the wear-resistant layer runs through the entire thickness, which can increase the service life.

The surface wear resistance level can reach T level (close to zero wear), far higher than ordinary composite flooring. Even if there are deep scratches (<4mm), they can be repaired through hot melt welding and polished to restore their original appearance.

Using non-toxic PVC raw materials, free of formaldehyde and recycled materials, and inhibiting bacterial growth through antibacterial treatment. Outstanding anti slip performance (friction coefficient is three times that of stone), reducing the risk of falling due to water induced roughness.

Sound absorption and noise reduction, capable of absorbing 15dB of noise. Elastic cushioning can reduce joint impact. Achieve B1 level fire and flame retardant effect, moisture-proof, anti slip, and mold resistant, suitable for sensitive environments such as laboratories.

Widely used in hospital operating rooms and wards, seamless welding technology avoids dirt hiding and is resistant to chemical disinfectant corrosion. Schools and kindergartens prioritize its anti slip and silent features, while sports venues utilize its high elasticity to reduce sports injuries. High traffic areas such as shopping malls and airports rely on their wear resistance (with a lifespan of over 10 years), while factory workshops value their oil resistance and easy cleaning properties.

According to market research, the penetration rate of homogeneous transparent PVC flooring in the medical and educational fields has exceeded 60%, and with the promotion of green building policies, it is expected that the global market size will exceed 5 billion US dollars by 2025. Its recycling characteristics (with a recovery rate of over 90%) also align with carbon neutrality goals, making it the preferred material for sustainable buildings.

相关推荐

- Carpet patterned plastic flooring

- Sports series PVC plastic flooring: an innovative solution for professional sports spaces

- Suspended flooring: innovative application of modular multifunctional flooring materials

- Rubber flooring: a comprehensive analysis of multifunctional and environmentally friendly flooring materials

- LENEN New Materials Co., Ltd.